Tire and Rubber Industry

WHY USE ALPHA DESCALER FG

Alpha Descaler FG is formulated to rapidly clean mineral Scale from passages in Watercooled or Heated equipment. It improves Efficiency, Lower Cost, Conserves Energy, and extends the usable Life of cleaning equipment. Safe on Steel, Iron, Brass, Copper, Plastic, Rubber and other materials found in most Water-Cooled, Heated Equipment. Used by circulating through water passages in the water side of Heat Exchangers, Coolers, Pumps, Boilers, Compressors, Condensers, Extruders, Banbury Mixers, Bead Insulator, Calendar Rolls, Tread Extruder, Molds, Cooling Towers, Furnaces, and Water Piping Systems. Fortified with Powerful non-Foaming, non-fuming, wetting and penetrating Agents.Safe degreasing solvents and Superior corrosion inhibitors to prevent corrosion of the Steel, Brass, or Copper Surfaces being cleaned. Does not contain cresols or other tar oil or coal tar that require SARA Title III, Section 313 spill loss or disposal reporting.

Most maintenance or Engineering Personnel know how difficult it is to clean a piece of machinery. Taking the piece of machinery out of production, which cost the Company down time and disassembling the equipment, only to find out it is Clogged with Water Deposits such as Calcium, Rust, or other Scale Build Up. Employee’s may rod out the equipment or using a high pressure water system, which takes Time and a lot of Man Hours. In some cases you will need a Crane or Fork Lift just to remove the Equipment from hard to get places, and This of Course, Cost’ the Company More Money and Time. Alpha Descaler FG will make it easier on your Company to Clean out the equipment.

Alpha Descaler FG is fully bio-degradable within 10 days and most of the time it can disposed of the Down The Drain after use. Please dispose of according to local rules and regulations. You Do Not have to heat the Alpha Descaler FG to a higher temperature before you circulate into whatever you might be cleaning. And once Again, Alpha Descaler FG Does Not Contain Toxic Cresols or Other Tar Oil, or Coal Tar that Require SARA Title III, Section 313 Spill Loss or Disposal Reporting.

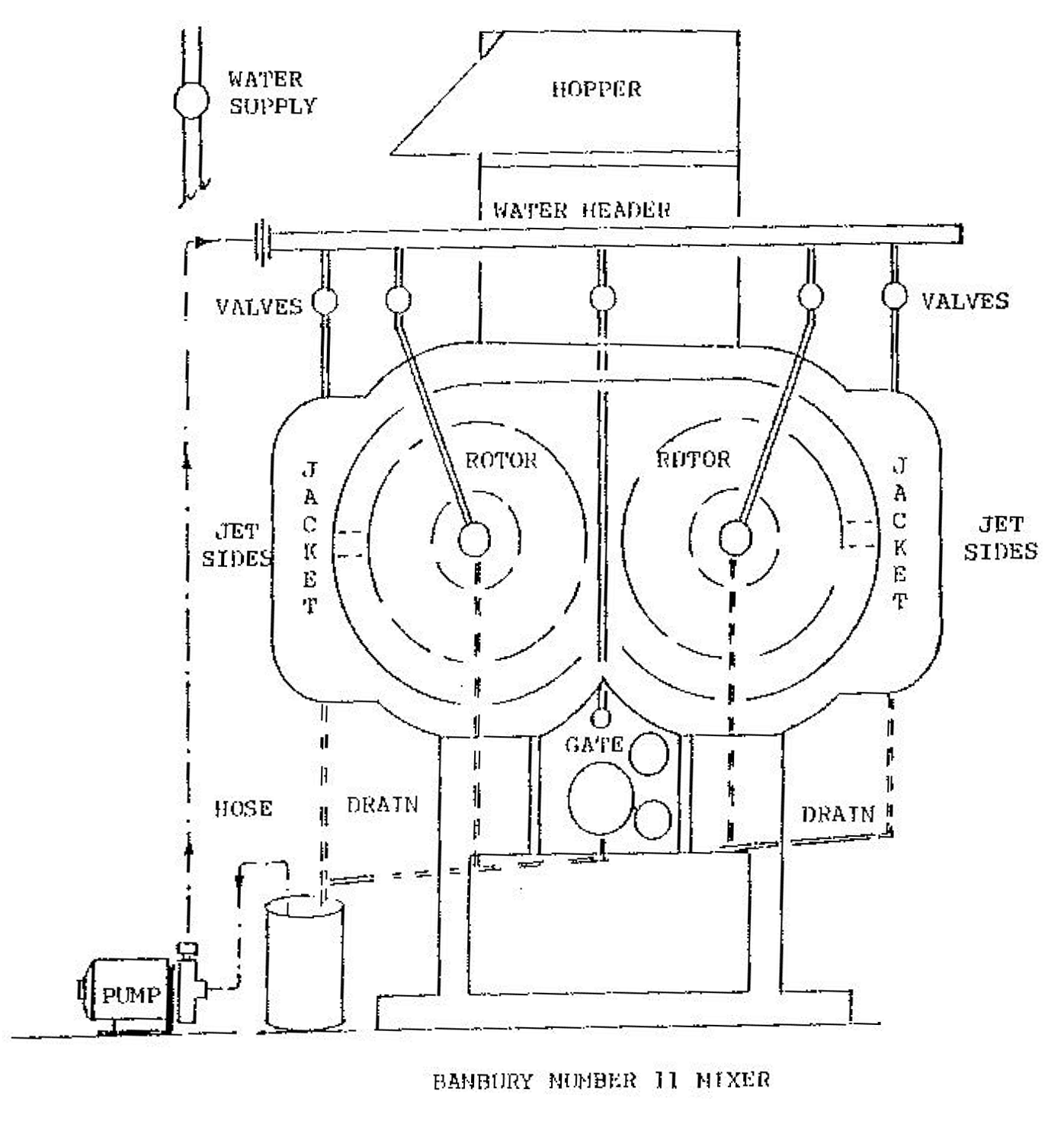

ALPHA DESCALER FG CLEANING OF BANBURY MIXER

Cleaning Banbury Mixers Procedures

- Take Banbury Mixer out of Service.

- Shut off supply water at the header of Banbury Mixer.

- Remove or Drain all water from Banbury Mixer.

- Connect the circulating pump discharge hose to water supply line on the Banbury Mixer.

- Connect return hoses from the Banbury Mixer (drain lines as well) to your return circulating tank.

- Close the water supply valves to gate and jacket on the Banbury Mixer.

- Circulate the Alpha Descaler FG into the Rotors to Purge remaining water in the system. Discharge this remaining to the sewer. Maintain Alpha Descaler FG circulation through this circuit.

- Open the water valve to the gate and maintain Alpha Descaler FG circulation throughout this circuit.

- Open the water valve to the jackets and maintain Alpha Descaler FG circulation through this circuit.

- If anyone circuit is not flowing properly, restrict the flow in other circuits of unit until the flow returns to normal.

- Circulate 28 to 30 gallons or 106 to 114 liters of the Alpha Descaler FG through all circuits of the Banbury Mixer until it’s cleaned. Approximately 2 to 3 hours.

- You should rotate the Rotors during the cleaning process to assure cleaning of all the Lobes of the Rotor.

- Flush all of the Alpha Descaler FG from all the circuits of the Banbury Mixer upon completion of cleaning with fresh water.

- Remove the circulation pump and hoses from the Banbury Mixer. The Unit is now ready for Operation.

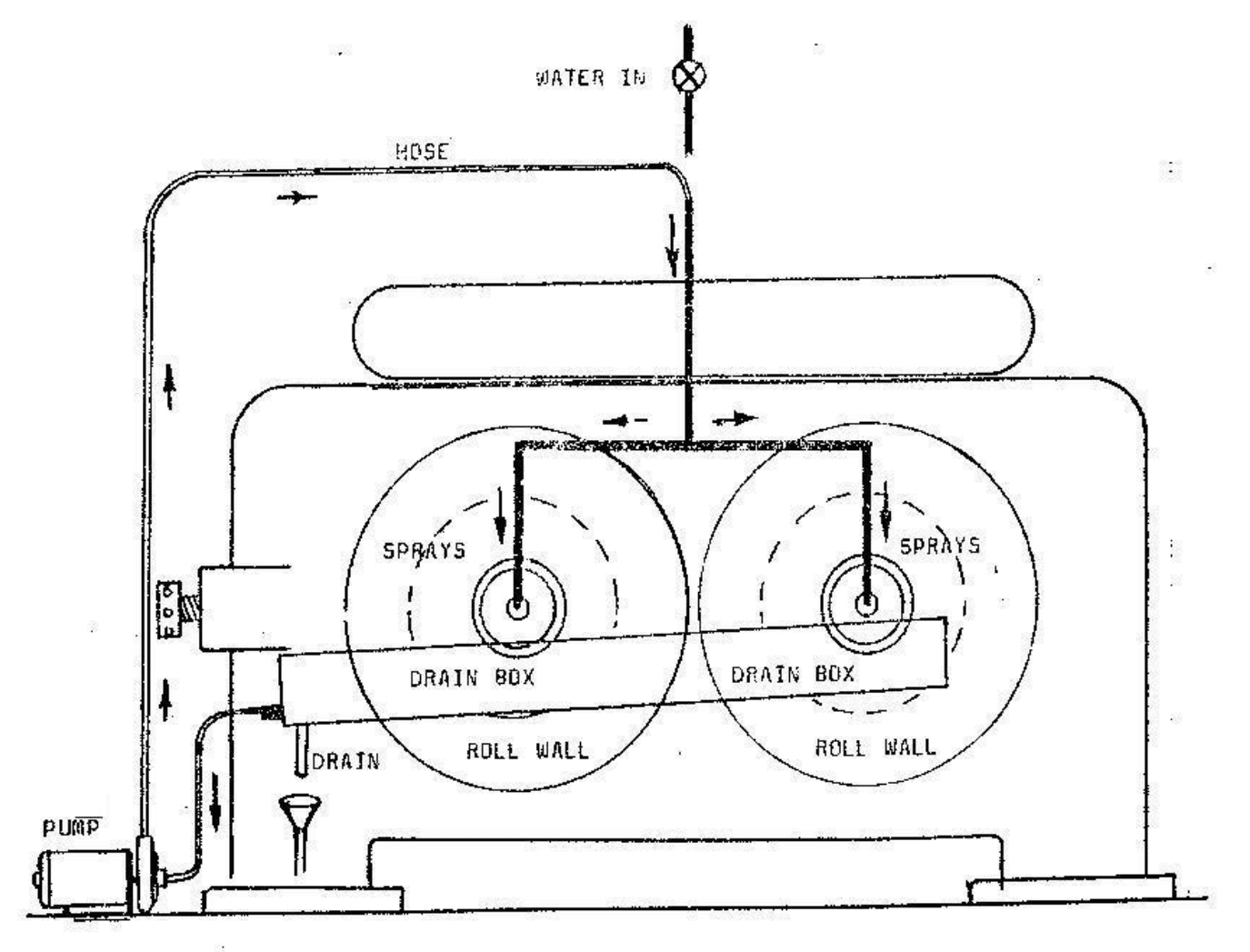

ALPHA DESCALER FG CLEANING OF BANBURY MILL

Cleaning The Banbury Mill

- Shut off the Banbury Mill and turn off the cooling water to the rolls.

- Remove as much of the water out of the rolls as possible.

- Plug the drain at the bottom of the drain box.

- Attached the circulation pump discharge hose to the fitting at the bottom of the drain box or in the drain piping.

- You might have to install a valve on top of the Banbury Mill so the Alpha Descaler FG can be circulate out of the Banbury Mill onto the circulation conatianer.

- Banbury Mills will hold about 30 gallons or 114 liters of the Alpha Descaler FG for proper cleaning. At first, add 15 gallons or 57 liters to the circulation container. Start circulating pump.

- It is advised to rotate the Rolls about every 30 minutes if possible.

- After one hour of circulation, add 10 gallons or 38 liters of the Alpha Descaler FG to your circulating tank.

- After 2 hours of circulation, add another 5 gallons or 19 liters of the Alpha Descaler FG to your circulating tank.

- There should now be a total of 30 gallons/114 liters of the Alpha Descaler FG being circulated through the Banbury Mill.

- Circulate the Alpha Descaler FG for 3 to 4 hours.

- Upon Completion of circulating, remove the Alpha Descaler FG by pumping it into the drain or another empty container.

- Fill the circulation container with water once the Alpha Descaler FG is removed and repeat the circulation process to flush the Banbury Mill out with fresh water.

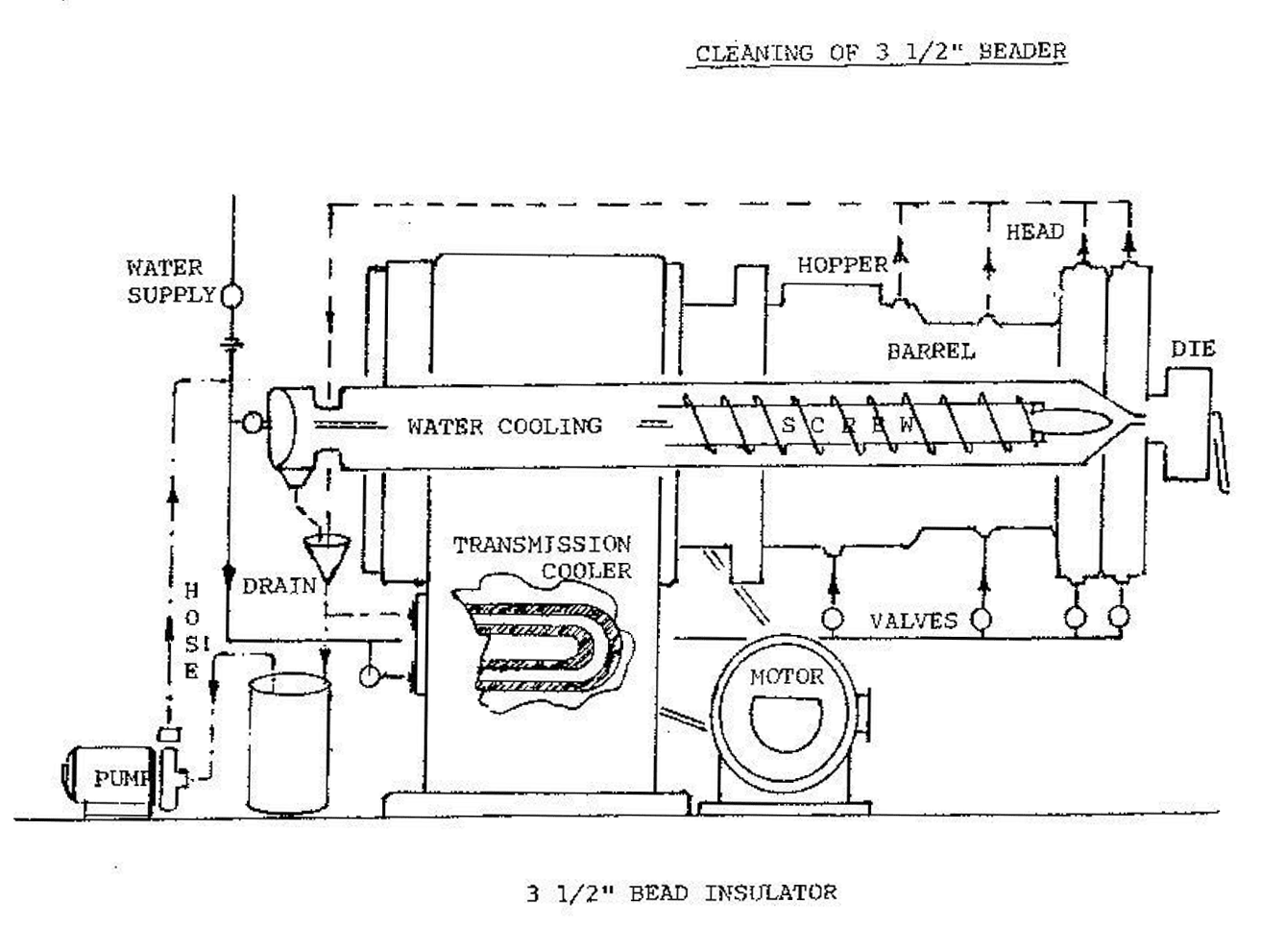

ALPHA DESCALER FG CLEANING OF 3 – ½” BEADER

Cleaning the 3 1/2” Beader

The bead insulator is being used in the Tire and Rubber plants to put a Rubber Coating on many strands of wire that is the bead for tires.

With the improper cooling of the six water circuits in the beader, it could led to the forming of water scale, calcium, lime, mud and rust deposits in the cooling system of the internal circuits, the right amount of thickness of soft rubber cannot be applied to the wire strands of the bead if the circuits are clogged.

- Close the water and steam supply valves to the Beader.

- Make sure all the water valves to various circuits are open fully. These valves are usually partially open to obtain desire cooling while the Beeder is operating.

- Remove all the water from the circuits of the Beeder.

- Place your discharge hose from your circulating pump to the water inlet piping of the Beeder.

- Place your suction hose from your circulating pump in the circulation container.

- Place the circulating tank under the drain connection of the Beeder. This is where the Alpha Descaler FG will be flowing back into the circulating container.

- Circulate the Alpha Descaler FG through all six circuits.

- During the Alpha Descaler FG circulation, close all but one of the circuits to assure that the circuit is open. Continue to open and close each and every water valve to each circuit to make sure all water circuits are being thoroughly clean.

- It should take between 45 minutes to 1 hour of circulating.

- After the needed time for circulation, shut down the circulating pump and disconnect the suction and discharge hose. Reconnect the water and steam supply lines and flush the Beeder with fresh water. You have completed the Alpha Descaler FG cleaning.

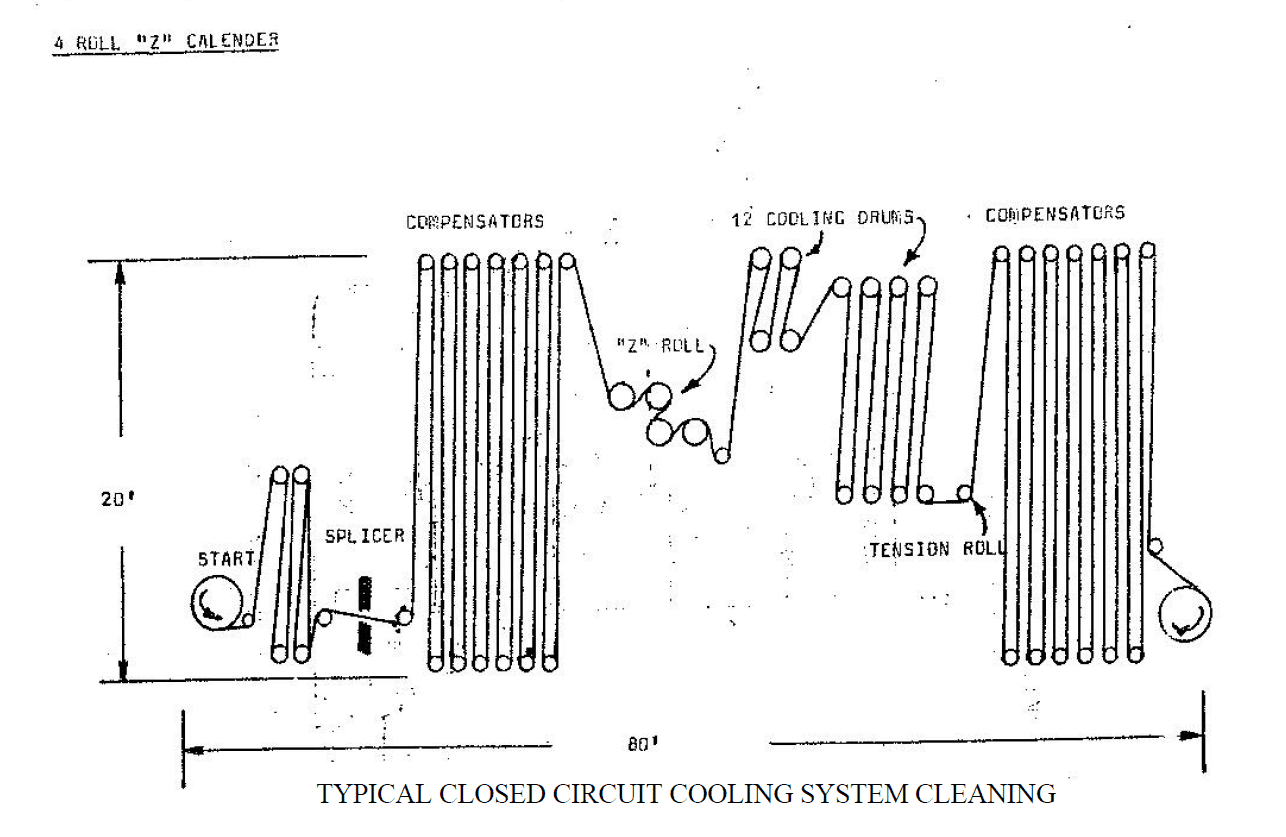

Cleaning the Closed Cooling Systems

The newer calendars are being cooled by a closed circuit cooling system. This type of system utilizes steam for heat and external cooling water through heat exchangers to maintain desired roll temperatures.

The closed circuit cooling for the rolls does not usally get clogged with scale build up to a minimum of make up water being introduce to the system.

Although the heat exchangers cooling side could get clogged with calcium, lime, rust and mud which will cause a heat increase. These following steps are used to clean the heat exchanger.

- While heat exchanger in place shut off the water supply to the heat exchanger.

- Drain the water from the heat exchanger and piping.

- Disconnect the water in/out lines from the heat exchanger.

- Connect the suction and discharge hose from the circulating pump to where you disconnected the water in/out lines on the heat exchanger.

- The amount of Alpha Descaler FG to be used will determine the size of the heat exchanger of each cooling system.

- Turn your circulating pump on so the Alpha Descaler FG will be circulating through the heat exchanger back into your circulating container.

- Circulate for about 1 to 4 hours, depending on the size of the heat exchanger. Call the Alpha Descaler FG manufacture for proper sizing.

- After the needed time for circulation, remove the Alpha Descaler FG from the exchanger, and flush the heat exchanger with fresh water.

- Connect the water in/out connection back to the heat exchanger and return the system back to its proper service.

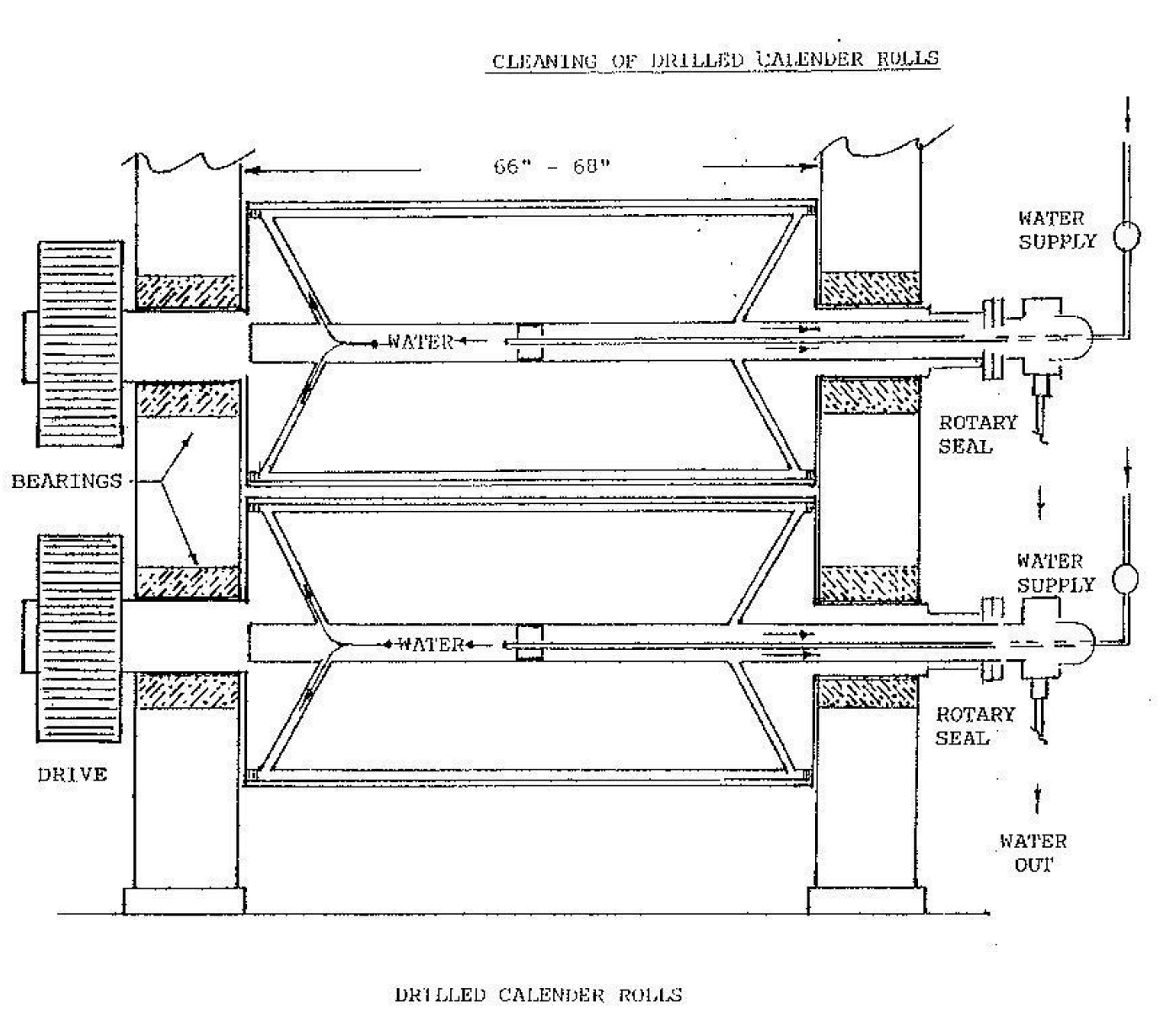

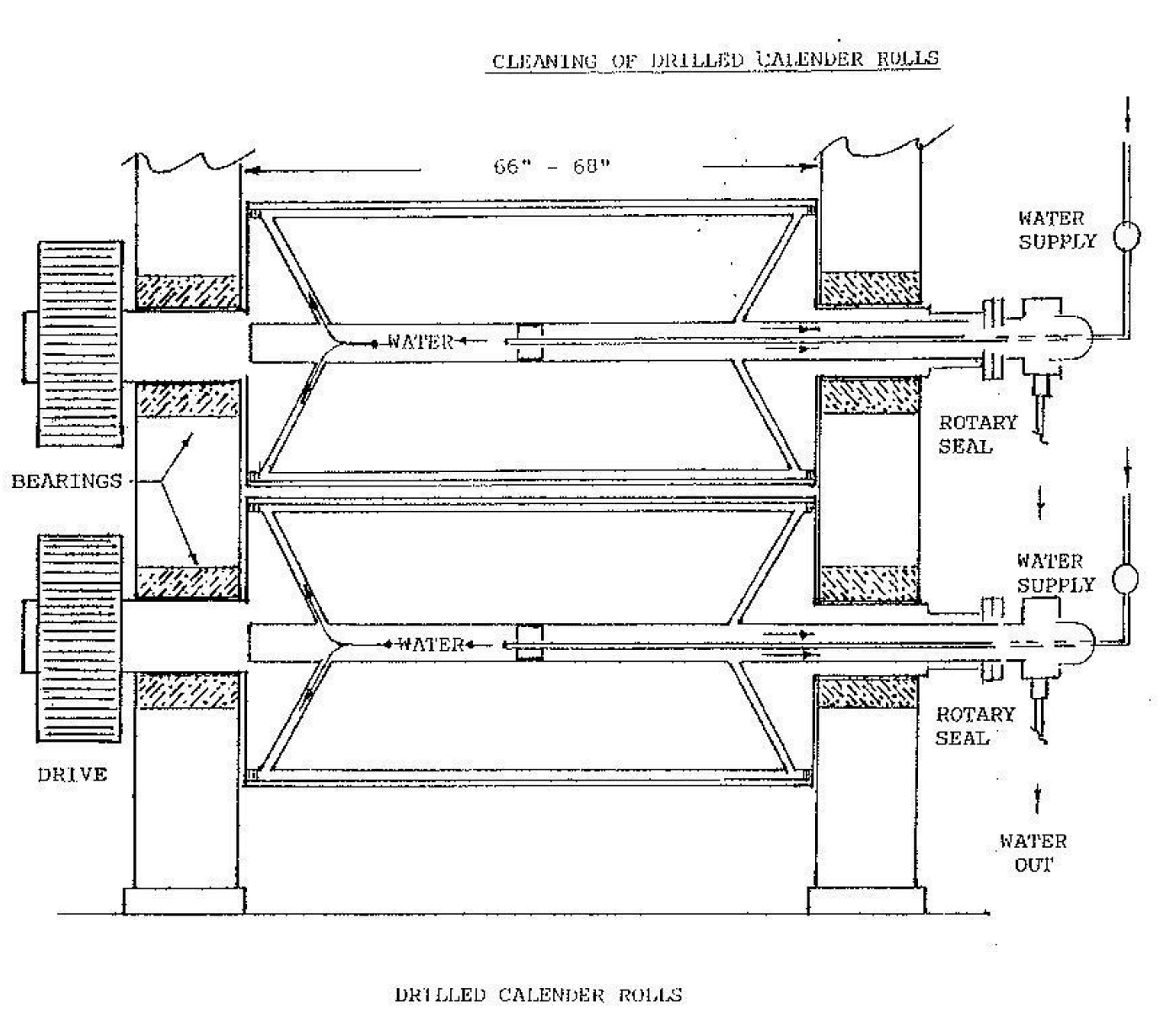

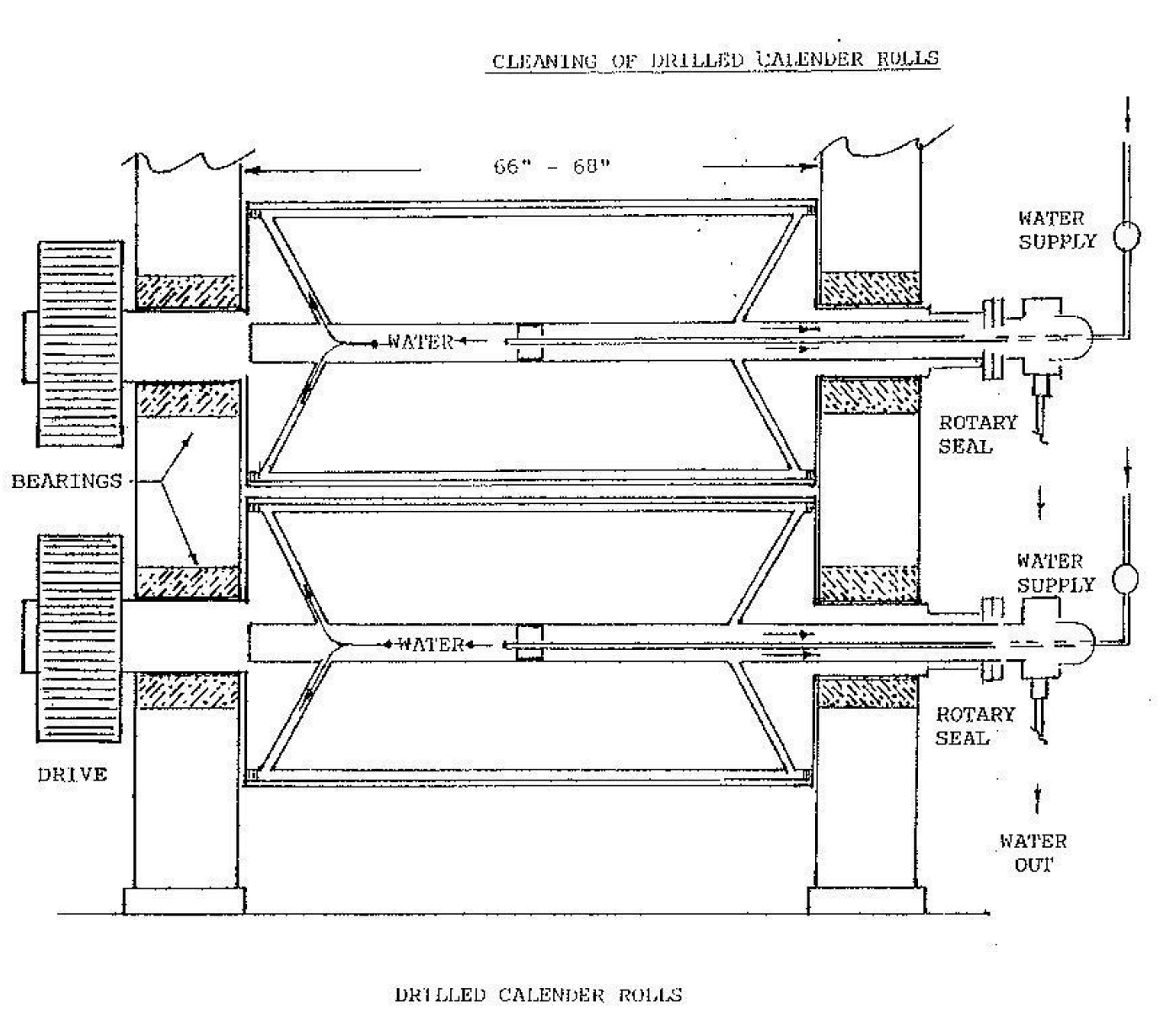

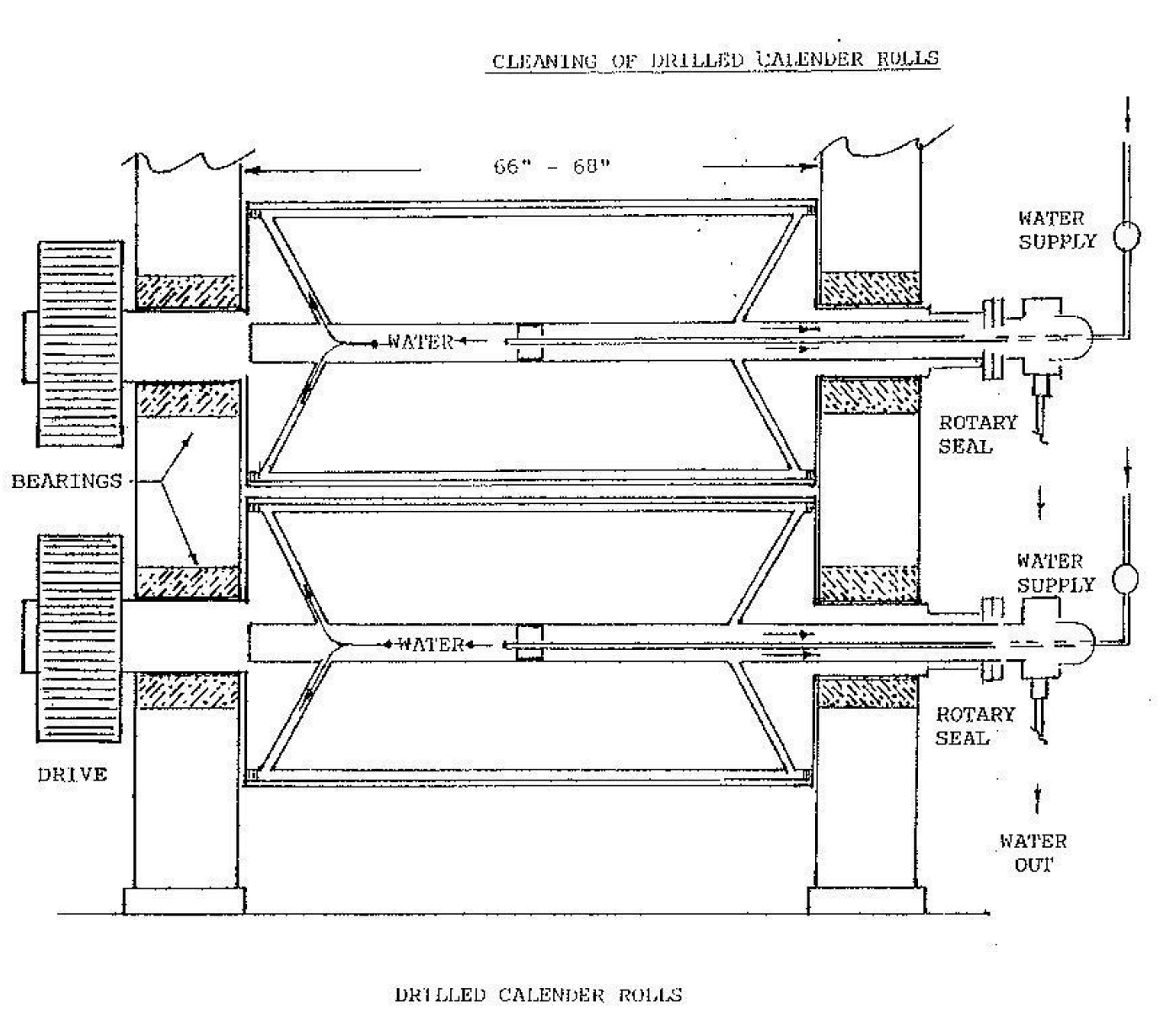

ALPHA DESCALER FG CLEANING OF DRILLED CALENDAR ROLLS

Cleaning of Drilled Calender Rolls

In order to keep the production in the Tire and Plants operating at full capacity, it is necessary to keep the Drilled Calender Rolls water capacity fully cleaned from scale build up. When you have scale build up it will cause a temperature increase and decrease the efficiency of the Drilled Calender Roll.

- Take the unit out of service.

- Turn off the water supply valves to the Calendar Roll.

- Remove as much water as possible from the system.

- You can clean one Roll or all the Rolls at one time.

- Place your discharge hose from your circulating pump to the water inlet piping of the Drilled Calendar Roll.

- Place your suction hose from your circulating pump in the circulating container.

- Place the circulating tank under the drain connection of the Drilled Calendar Roll. This is where the Alpha Descaler FG will be flowing back into the circulating tank.

- Circulate about 10 gallons or 38 liters of Alpha Descaler FG for each roll to be cleaned. A system with 4 Rolls will require 40 gallons or 151 liters of the Alpha Descaler FG.

- After the circulating have been turned on, circulate the Alpha Descaler FG for 2 hours.

- After the needed time for circulation, shut down the circulating pump and disconnect the suction and discharge hoses. Drain the Alpha Descaler FG from the system, and flush with water.

- Reconnect the water supply lines to the system and return the Rolls to service.

ALPHA DESCALER FG CLEANING OF 84” MILL ROLL

Cleaning 84” Mill Roll

- Shut down unit and turn off the water supply to the 84” Mill Roll.

- Remove as much water as possible from the system.

- You will need to plug the drain in the of the drain box.

- Place your suction hose from your circulating pump to the fitting at the bottom of the drain box or in the drain piping.

- Place your discharge hose from the circulating pump to the water inlet going into the 84” Mill Road.

- Add 12 to 15 gallons or 45 to 57 liters of the Alpha Descaler FG to the circulating pump tank, then turn on the circulating pump and let the Alpha Descaler FG through the 84” Mill Roll.

- The 12 to 15 gallons/45 to 57 liters of the Alpha Descaler FG should be enough for both Rolls.

- It is advised to rotate the rolls about every 20 minutes.

- After 1 hour of circulating add 10 more gallons or 38 liters of the Alpha Descaler FG to the circulating tank.

- After 2 hours of circulating the Alpha Descaler FG, add 5 gallons or 19 liters more to the circulating tank.

- By now there should be approximately 30 gallons or 114 liters of the Alpha Descaler FG being circulating through both of the rolls.

- This should circulate the Alpha Descaler FG for a total of 4 hours.

- Upon completion of the circulation, remove the Alpha Descaler FG by pumping it into the drain, or another empty container.

- Fill the circulating container with water once the Alpha Descaler FG is removed and repeat the circulation process to flush the 84” Mill Roll out with fresh water.

- Reconnect the water supply line the Mill and return the Mill back to service.

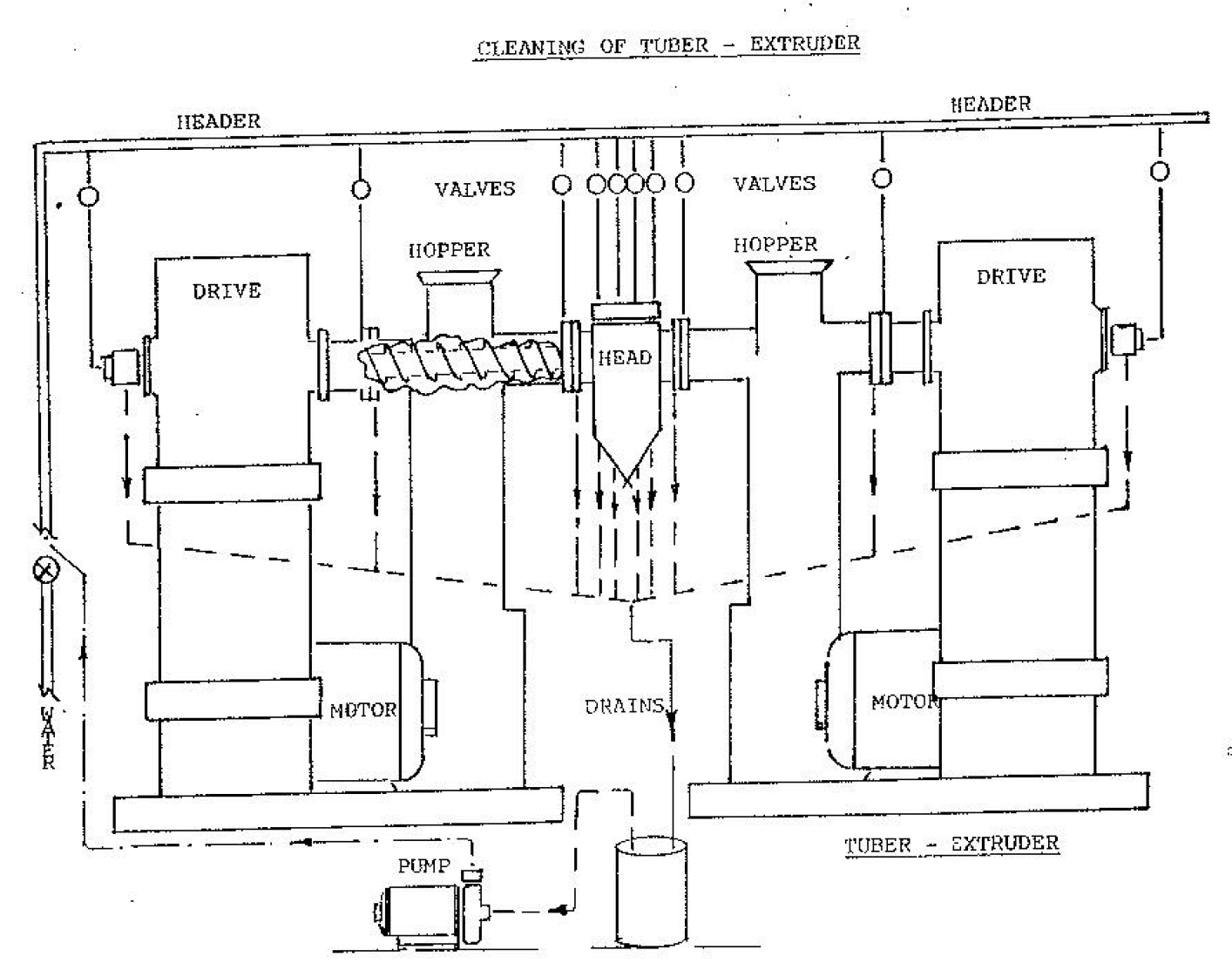

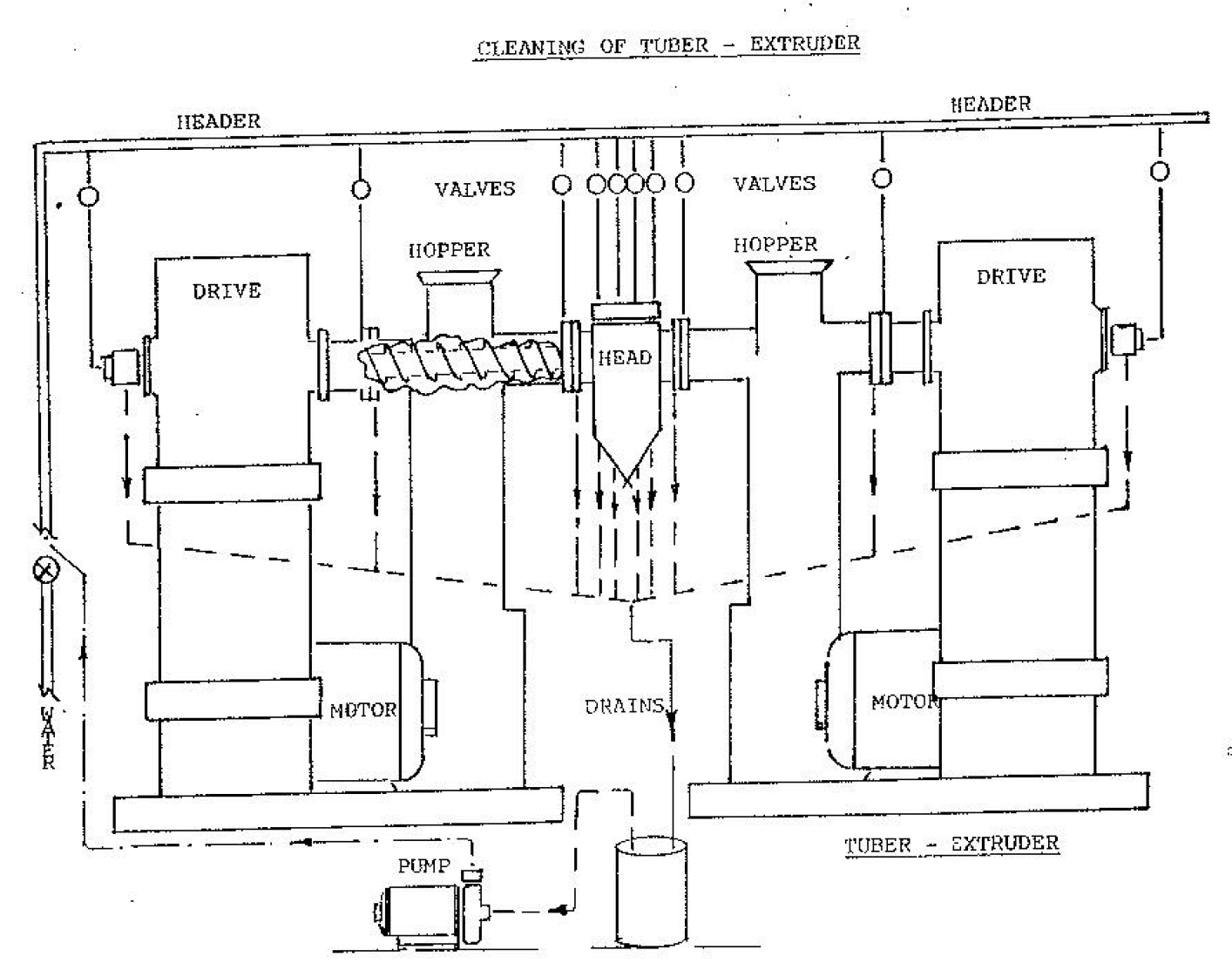

ALPHA DESCALER FG CLEANING OF TUBER – EXTRUDER

Cleaning Tuber-Extruder (12″)

The tuber –extruder is used to extrude grades of rubber stock onto what ends up as the end product. There are two drives, two hoppers, two barrels, two screws and one head. There are usually five water circuits on each half of the unit.

Tuber-extruders come in different diameter screws. The following instructions are for the removal of accumulated water scale, lime, mud, rust and other water formed debris that deposits on the water side of this piece of equipment.

- Closed the water supply valve to the Extruder.

- Make sure all of the water valves to each circuit are open. These valves only part open to obtain the desire cooling while the Extruder is in operation.

- Remove all of the water from all the circuits.

- Place your discharge hose from your circulating pump to the water inlet piping to the Extruder.

- Place your suction hose from your circulating pump in the circulating container.

- Place the circulating tank under the drain connections.

- This Extruder will hold 30 gallons or 114 liters of the Alpha Descaler FG through all of the cooling circuits.

- During the Alpha Descaler FG circulation, close all but one of the circuit to assure this circuit is open and the Alpha Descaler FG is cleaning. Continue to open and close each and every water valve to each circuit to make certain all of the circuits are thoroughly clean.

- The cleaning of this Extruder should take around 3 hours of circulation.

- After the needed time for circulation, shut down the circulating pump and disconnect the suction and discharge hose. Reconnect the water supply lines and flush the Extruder with fresh water. You have completed the Alpha Descaler FG cleaning.

ALL PRODUCTS

If you need consulting beyond the scope of a complementary sales inquiry, please contact us by email.