Heat Treating Industry

Water is a crucial medium of cooling in the heat-treating industry. Most equipment in this industry use water to efficiently and effectively cool the equipment. But it is for the heating of water that allows for water scale, rust, lime and mud & other minerals to get attached to equipment surfaces. Various water problems arise from these deposits and will affect operating efficiencies, causing downtime and sometimes shutdowns. A common occurrence within the furnace is the build up of deposits on the distribution plates causing cooling water paths to become blocked, significantly decreasing efficiency. The resulting channeling through diminished passages results in hot spots and diminished cooling. Alpha Descaler FG is ideal to remove these deposits.

Water is a crucial medium of cooling in the heat-treating industry. Most equipment in this industry use water to efficiently and effectively cool the equipment. But it is for the heating of water that allows for water scale, rust, lime and mud & other minerals to get attached to equipment surfaces. Various water problems arise from these deposits and will affect operating efficiencies, causing downtime and sometimes shutdowns. A common occurrence within the furnace is the build up of deposits on the distribution plates causing cooling water paths to become blocked, significantly decreasing efficiency. The resulting channeling through diminished passages results in hot spots and diminished cooling. Alpha Descaler FG is ideal to remove these deposits.

All water-cooled heat-treating equipment will function properly and do a satisfactory job if cooling water circuits are kept clean and free of water borne sedimentation (cool down period will be shortened).

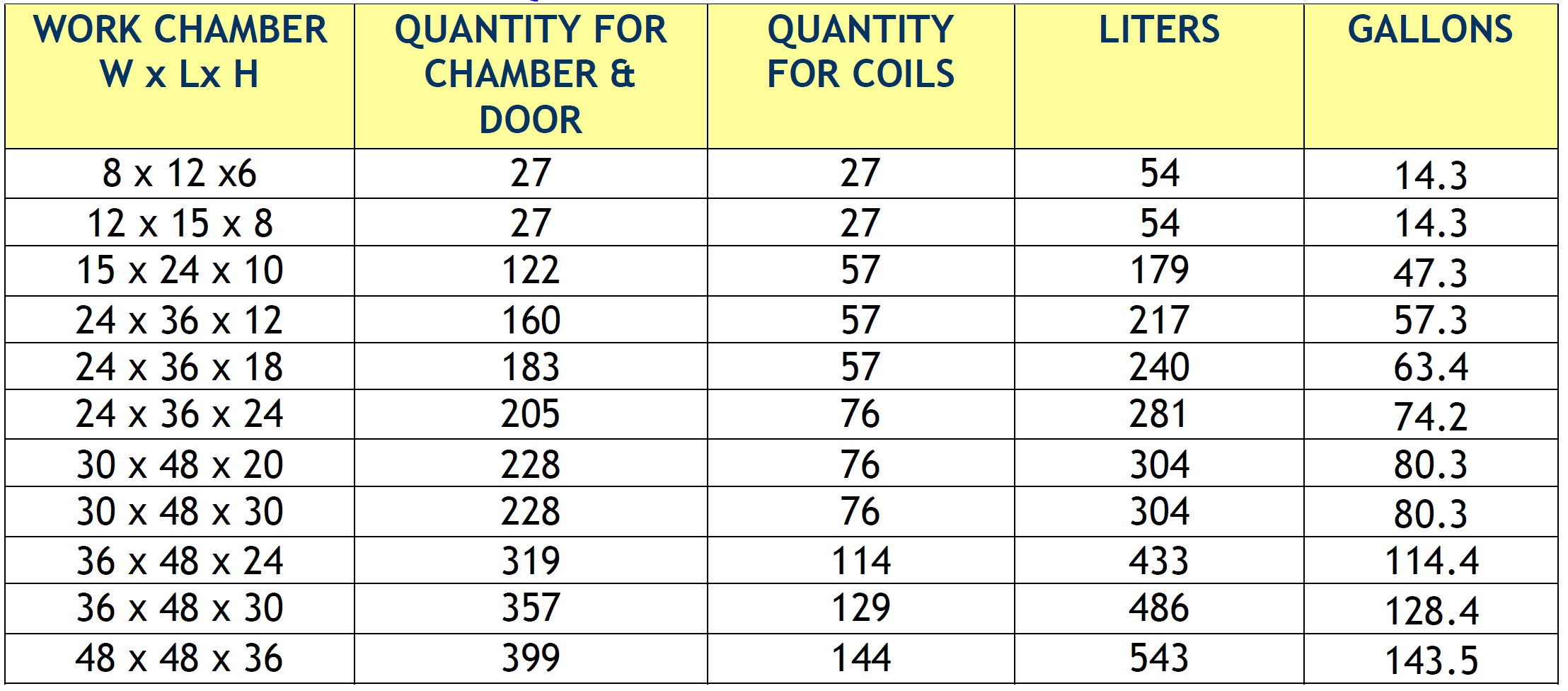

ALPHA DESCALER FG QUANTITIES

CLEANING FACTS:

- Because Alpha Descaler FG is non-corrosive and non-fuming, it is safe on cast iron doors, chambers, manifolds, valves and piping, copper tubing and diffuser pumps, rubber hoses and gaskets, in fact all water passages found in the heat-treating industry.

- Water conditions, usage and temperatures encountered will determine Alpha Descaler FG cleaning intervals. However it is optimal to operate between 0°F / -18°C and 180°F / 82°C.

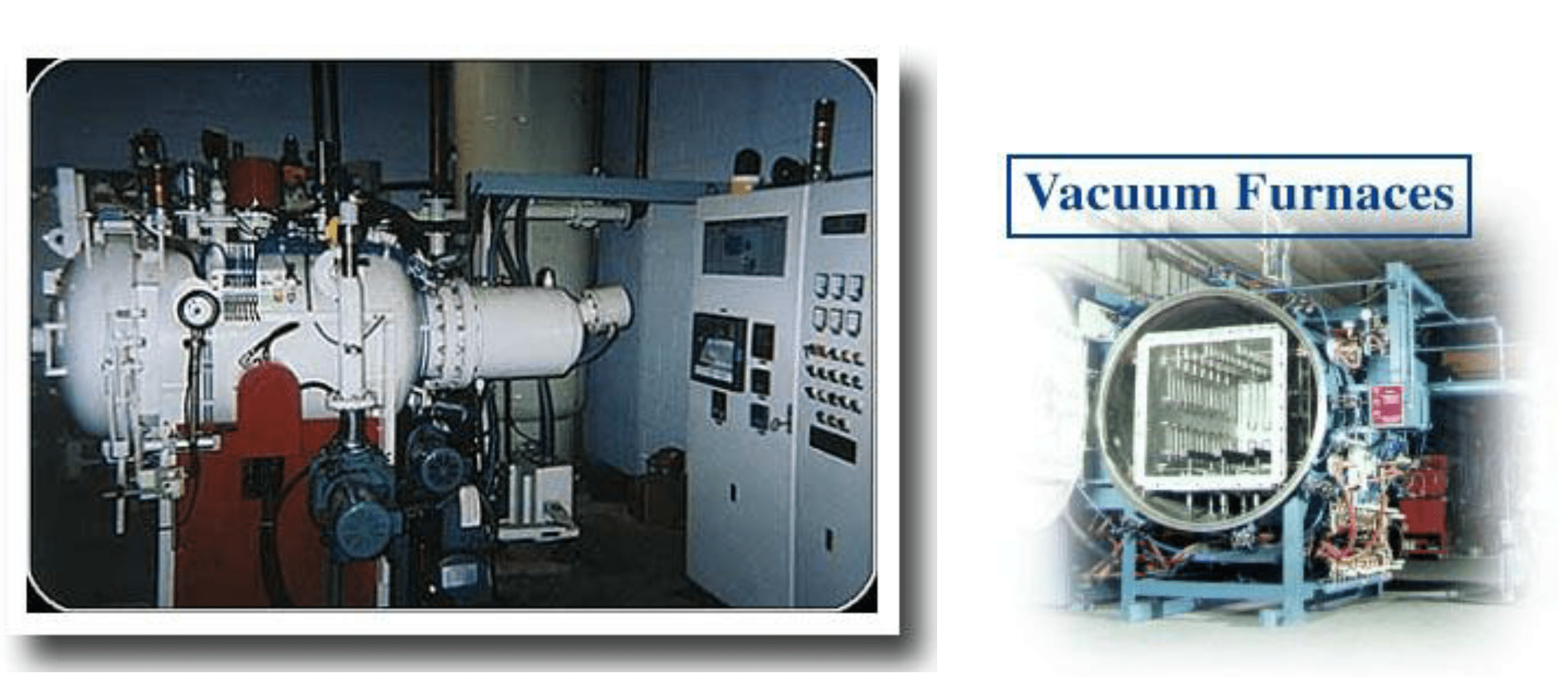

- Some of the equipment in the heat-treating industry that can be cleaned using Alpha Descaler FG; Circulating Fans, Heat Exchangers, Vacuum Furnaces, Induction Heating Systems, Evaporative Cooling Towers, Sump Tanks, Quench Tanks, Roller Bearings, Diffusion Pumps and Refrigerated Chiller

ALL PRODUCTS

-

Alpha Descaler

US $ 175.00 – US $ 1,485.00 Select options This product has multiple variants. The options may be chosen on the product page -

Alpha Descaler Extra Strength

US $ 250.00 – US $ 2,420.00 Select options This product has multiple variants. The options may be chosen on the product page -

Alpha Descaler FG

US $ 160.00 – US $ 1,210.00 Select options This product has multiple variants. The options may be chosen on the product page -

Alpha Descaler FG Extra Strength

US $ 210.00 – US $ 1,650.00 Select options This product has multiple variants. The options may be chosen on the product page

If you need consulting beyond the scope of a complementary sales inquiry, please contact us by email.