Chillers & Condensers

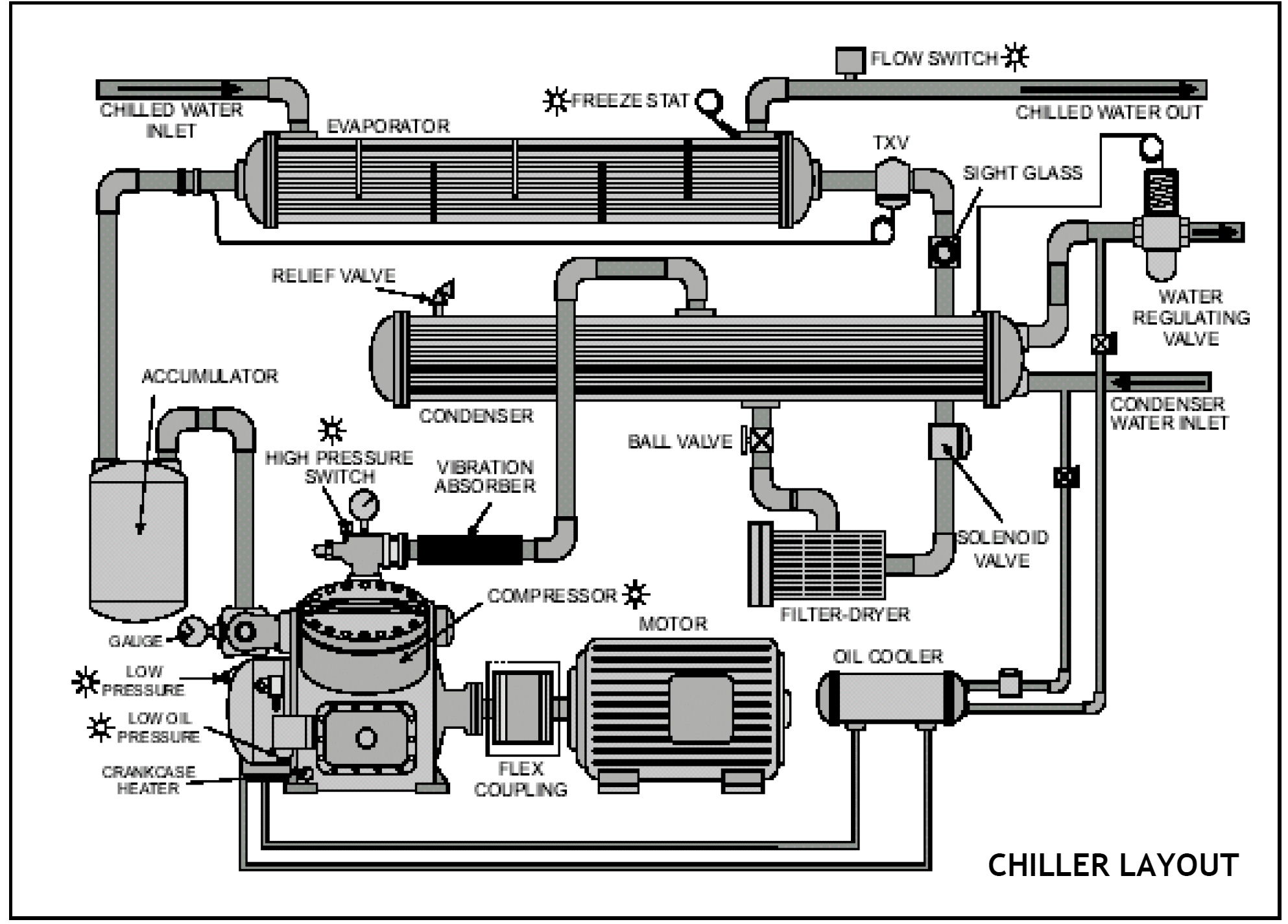

Chillers typically consume more electricity than any other single energy-consuming device in a factory or commercial building. Chillers are similar to air conditioners found in any home; except that chillers supply cool water and home air conditioners supply cool air. Chillers include a compression, evaporator and condenser along with ancillary equipment to move air. In simple terms, chillers remove heat from warm water that enters the unit, and return cold water to the central air conditioning system. The cool water from a chiller is eventually pumped through a heat exchanger, which cools the building’s air or for refrigeration.

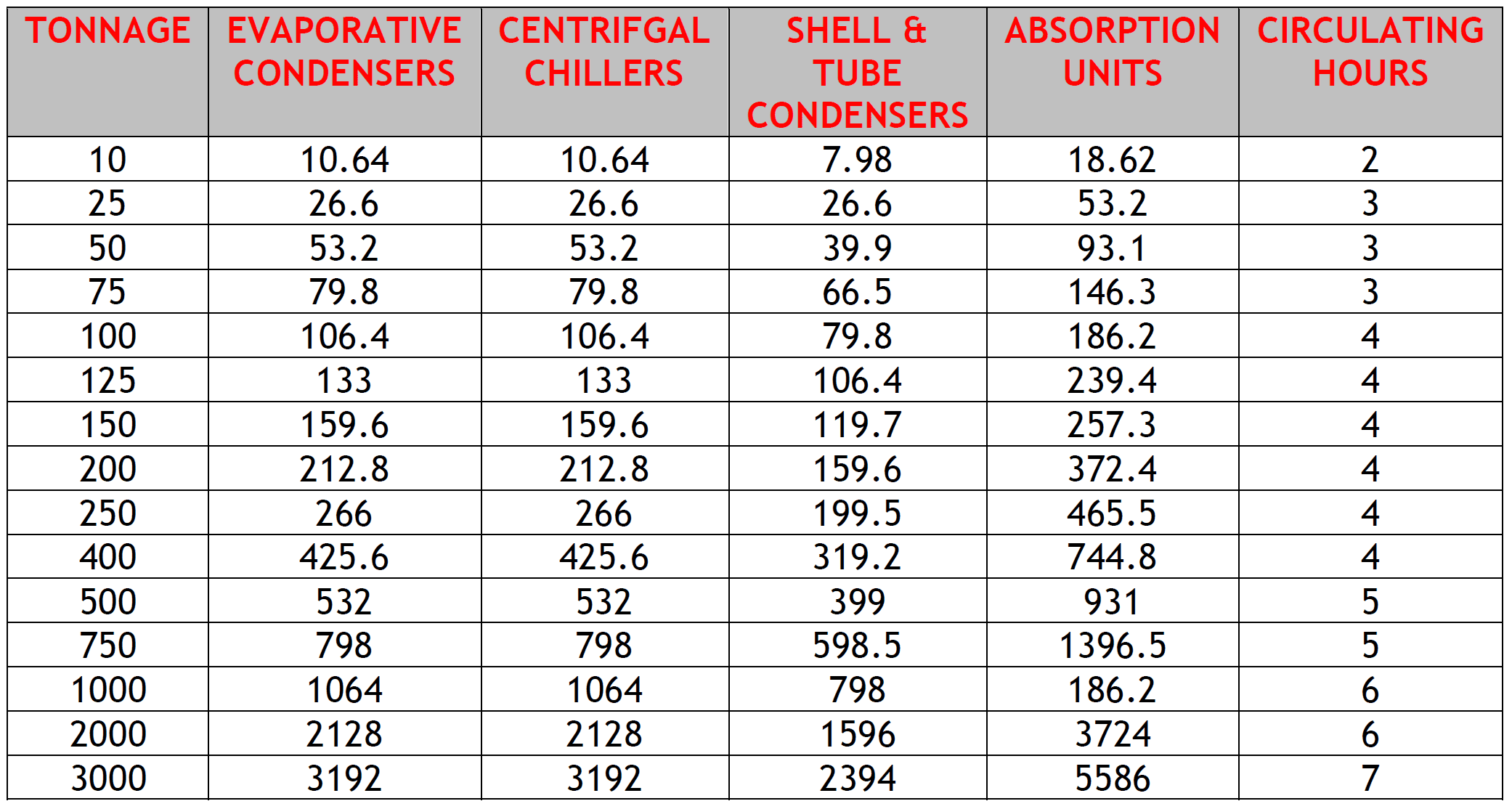

Optimum heat transfer relies on clean surfaces on both the refrigerant and water side of the chiller tubes. Typically, the waterside of the condenser needs the most attention because evaporative cooling towers have an open loop and new water is introduced continuously. Thus, these surfaces need to be kept clean of water formed deposits especially water scale. Scheduled usage of Alpha Descaler or Alpha Descaler FG will keep your equipment scale and rust free working at top efficiency within a few hours. Why?

Whenever there is a deposit of any type on a heat transfer surface, it retards heat transfer. This is referred to as “thermal resistance” and requires a corresponding increase in energy to overcome it. Major manufacturers of air conditioning equipment generally design condensers and chiller heat exchangers to operate at a maximum “thermal resistance” or “fouling factor” of 0.0005. As a result, with only 0.036 inches (about 1/32”) of deposit corresponds to an increase in energy costs of over 30%!

This 30% increase in costs relates to a hardness scale (calcium carbonate) deposit. Iron deposits (same thickness) are greater insulators and therefore have lower heat transfer coefficients. The actual heat transfer coefficient of a fouling/deposit (scale, rust, lime, corrosion products, dirt and silt) depends on what it is. Most definitely, any fouling/deposit contributing a fouling factor (thermal resistance) will increase electrical consumption and decrease efficiency. The increase in electrical energy takes place in the compressor. Scale deposits increase the resistance to heat transfer, and in the condenser higher refrigerant gas temperatures will result. Higher refrigerant gas temperatures mean higher gas pressures, which require greater energy to compress the refrigerant. Therefore, there is an increase in electrical power to operate the compressor.

To minimize such potential energy losses requires an ongoing, daily monitoring of kW consumed per ton of refrigerant/air conditioning being generated. Reason being is we need to recognize inefficient operation and correct it. Each day of inefficient operation means excess energy expenditures and high operational costs.

Alpha Descaler is specially designed to rapidly dissolve and remove the toughest water deposits practically any type of water cooled, operated or heated equipment.

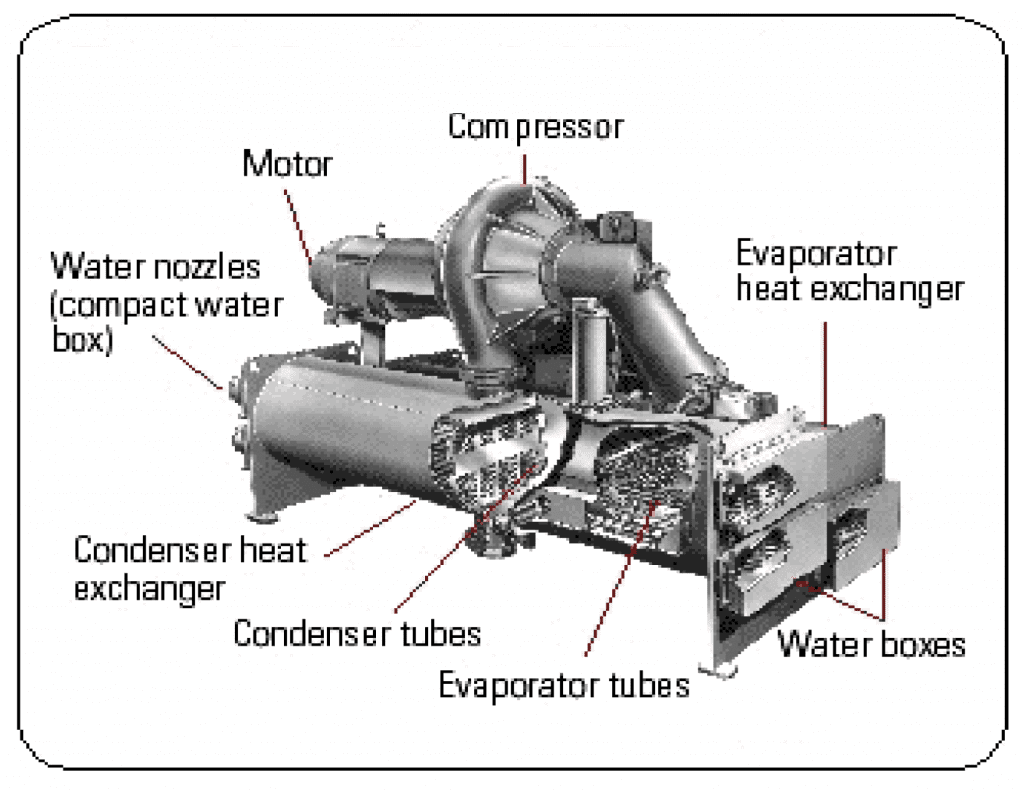

CENTRIFUGAL CHILLERS

In centrifugal chiller units, water scale is mostly encountered in the condenser and cooling tower.

With Alpha Descaler the removal of water formed deposits can be removed while the unit is still in operation by the addition of Alpha Descaler FG or Alpha Descaler

to the cooling tower.

The dissolved water scale, rust, mud and lime deposits included the biodegradable and expended Descaler will be conveniently dissipated by evaporation loss, make-up water and bleed off.

Regular cleaning with Alpha Descaler will maintain peak operating efficiency during high demand cycles and give maximum rated output.

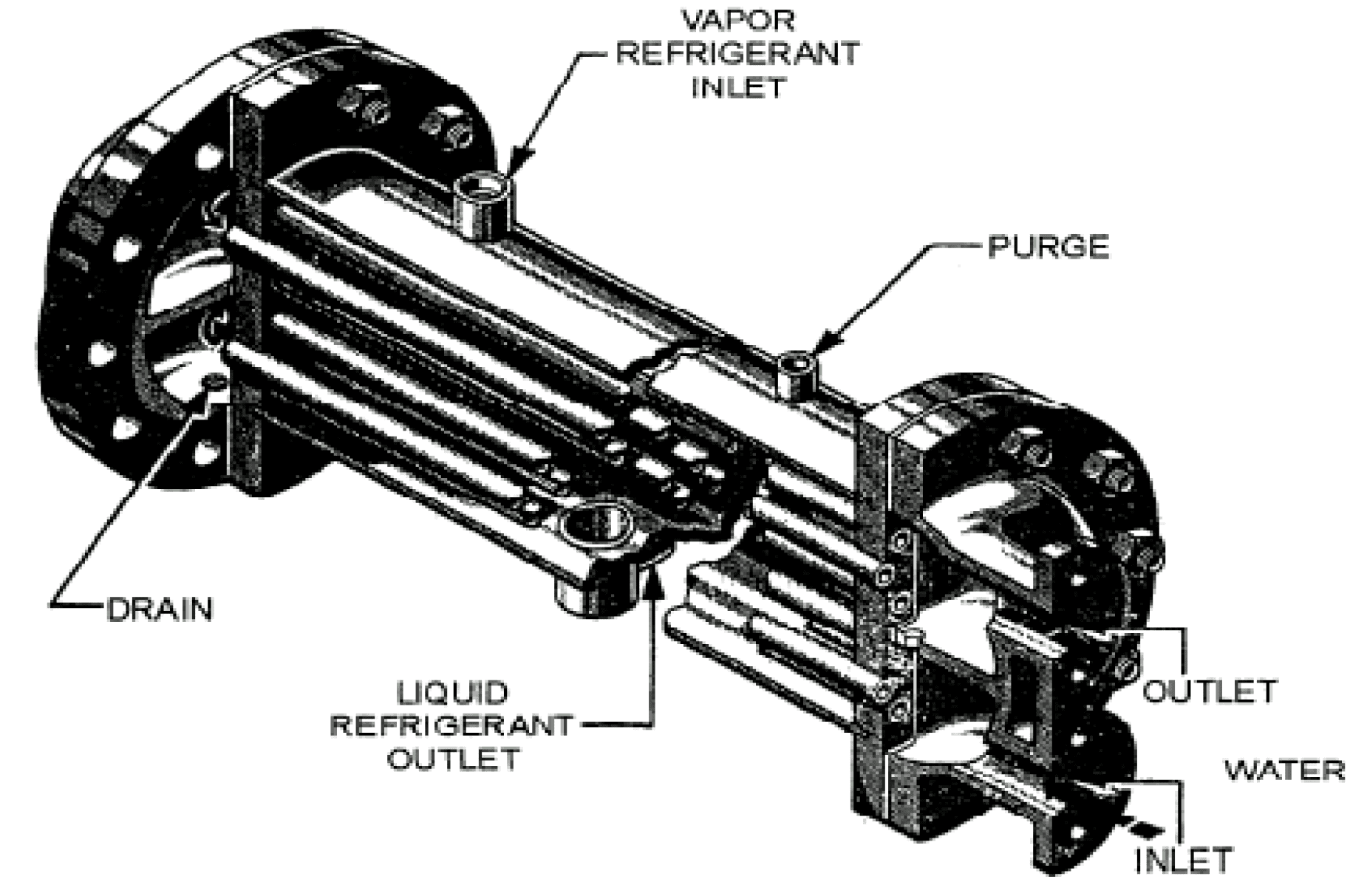

SHELL & TUBE CONDENSERS

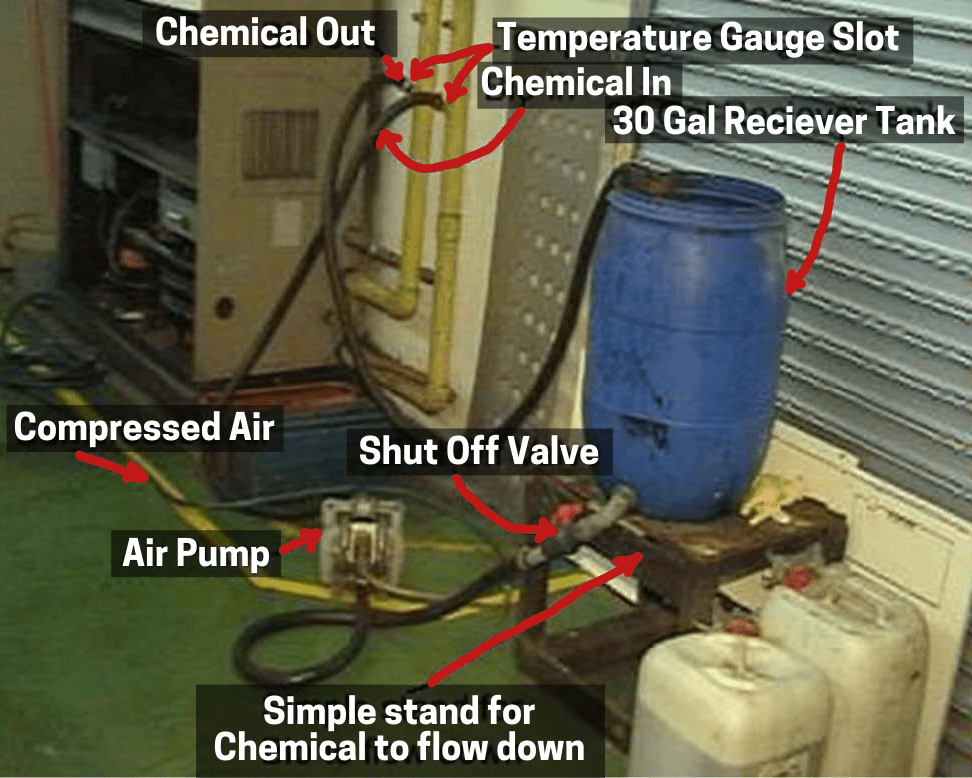

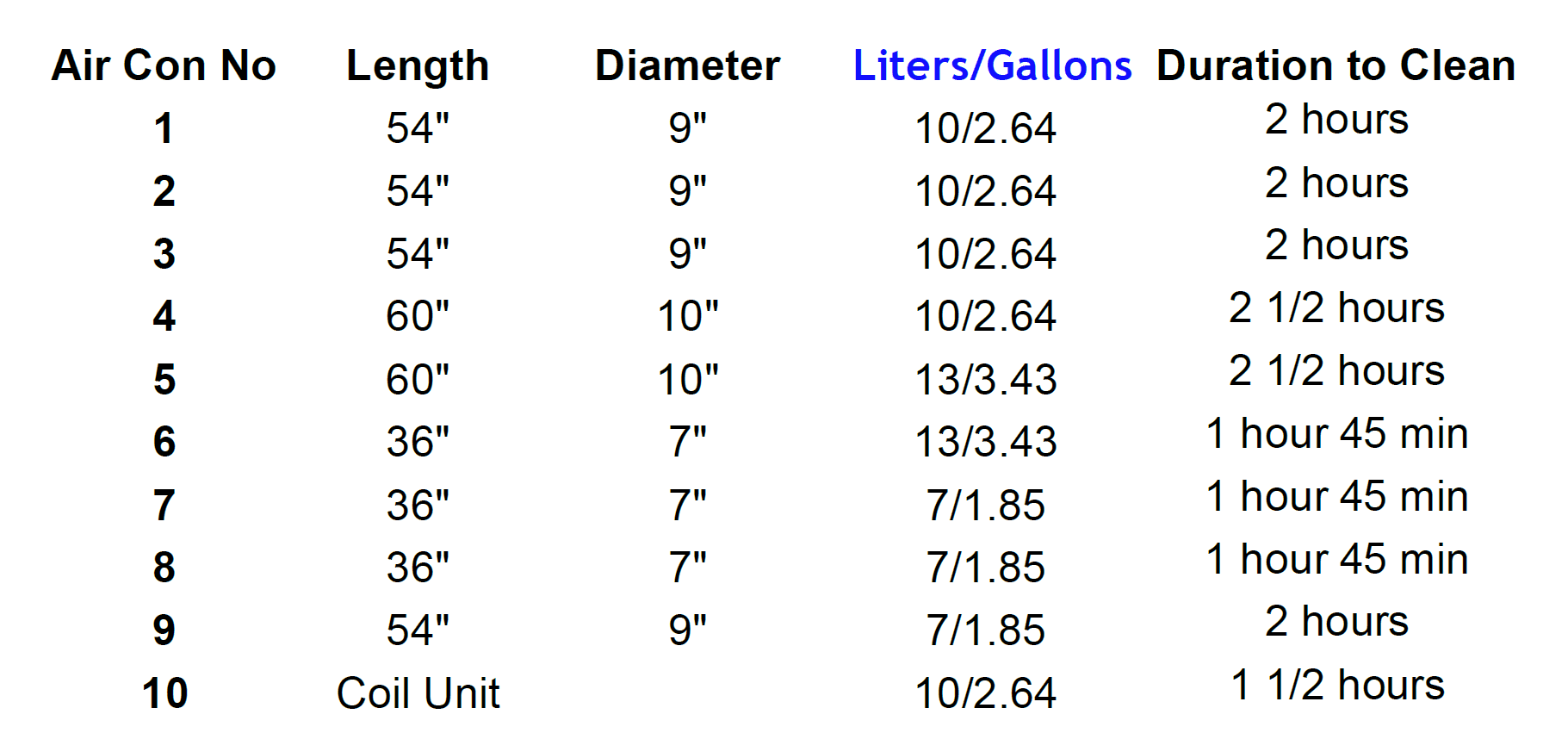

Water scale deposits in the condenser coils causes the compressor to kick out on high head pressure and lowers the cooling capacity of the unit. To remove these insulating water scale, lime, mud, and rust deposits formed on the inside of the shell & tube condensers, simply circulate Alpha Descaler or Alpha Descaler FG in through the water supply and out through the water return. Circulate for the recommended time or until unit is cleaned, then flush with water.

Replace zinc or magnesium anodes and return unit back to service. Depending on the size of the unit cleaning could be accomplished within 2-8 hours!

WCPU CLEANING

Typical WCPU Audit

Cleaning notes:

- Since most Condensers and Evaporators are of Shell & Tube design, cleaning methods are similar to that as stated in the Heat Exchanger section.

- Most Shell & Tube Evaporators are of a closed-loop design and do not need to be cleaned as frequently as condensers.

- With Coil Condensers, make sure the welding joint between the inner copper tube (water-side in and out) and the water supply pipe, normally Galvanized Iron, is not badly rusted. These joints are the first to give way. If it is badly rusted do not clean unit.

ALL PRODUCTS

-

Alpha Descaler

US $ 175.00 – US $ 1,485.00 Select options This product has multiple variants. The options may be chosen on the product page -

Alpha Descaler Extra Strength

US $ 250.00 – US $ 2,420.00 Select options This product has multiple variants. The options may be chosen on the product page -

Alpha Descaler FG

US $ 160.00 – US $ 1,210.00 Select options This product has multiple variants. The options may be chosen on the product page -

Alpha Descaler FG Extra Strength

US $ 210.00 – US $ 1,650.00 Select options This product has multiple variants. The options may be chosen on the product page

If you need consulting beyond the scope of a complementary sales inquiry, please contact us by email.