Boilers

Boiler Basics

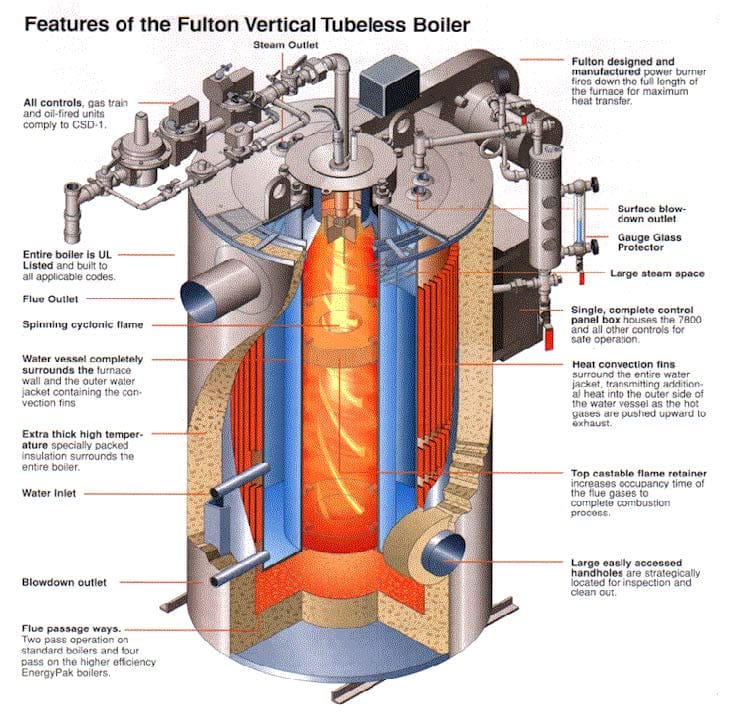

In a boiler, fuel and air are mixed and injected into a combustion chamber, where the fuel is burned to produce heat. This heat is then transferred to water that is confined in a vessel and/or in tubes. Depending on the type of system, the water is distributed to its intended use as either hot water or steam. In a fire-tube boiler, a boiler in which the hot combustion gases travel through tubes that are immersed in water to be heated or converted to steam. A water-tube boiler, a boiler in which water to be converted to steam is contained within tubes and hot combustion gases are outside the tubes. All boilers have the following three basic components:

Burner: A mechanical device used to inject fuel into the boiler’s combustion chamber. Most burners also inject air in proportion to the amount of fuel and ensure mixing of the fuel and air.

Tubes: In fire-tube boilers, steel conduits through which the hot gases of combustion pass. Tubes separate the hot gases from the water and transfer heat to the water. Water passes through the tubes in a water-tube boiler.

Stack: The stack is a passage through which the combustion gases are exhausted to the atmosphere. The gases in the stack are referred to as stack gases or flue gases.

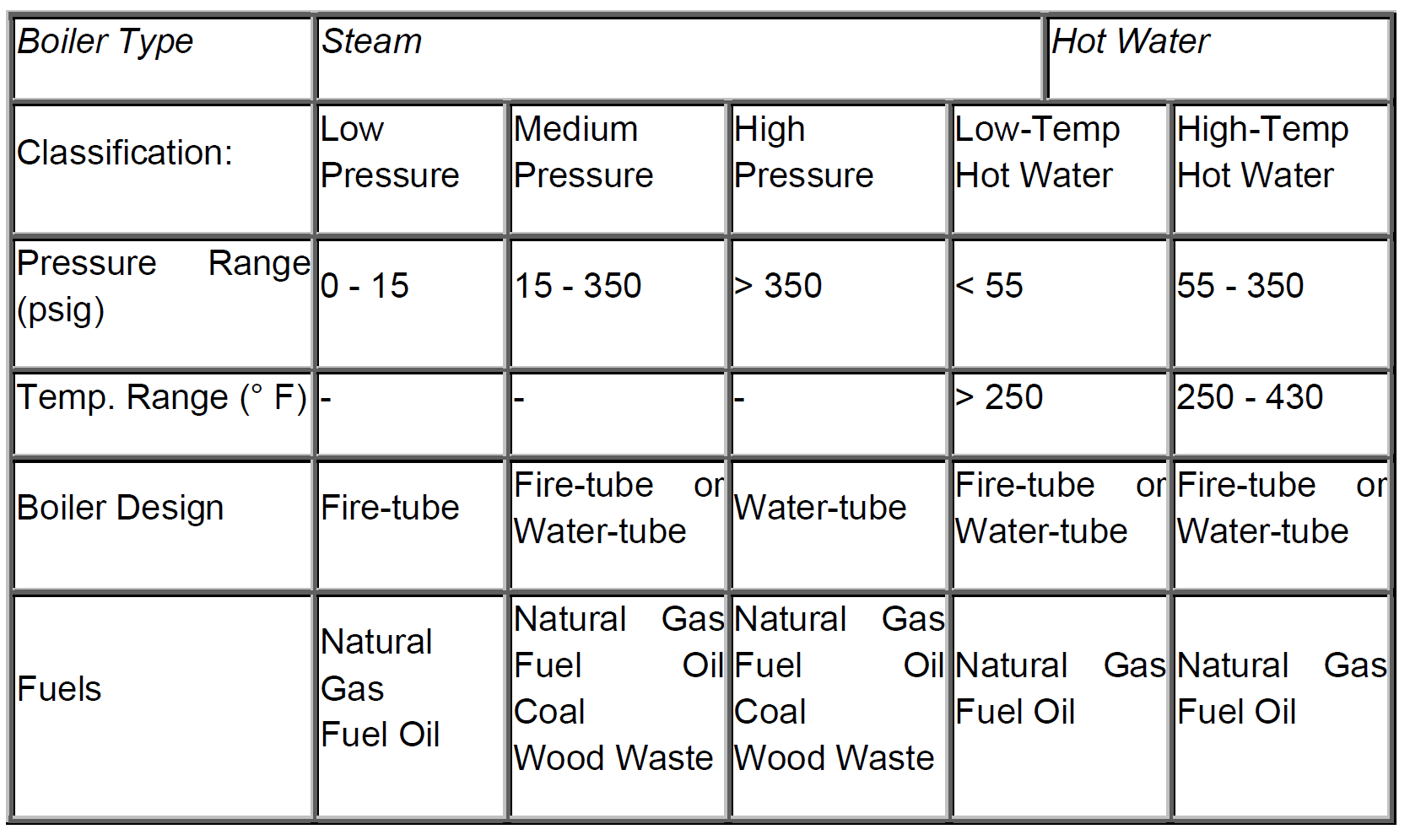

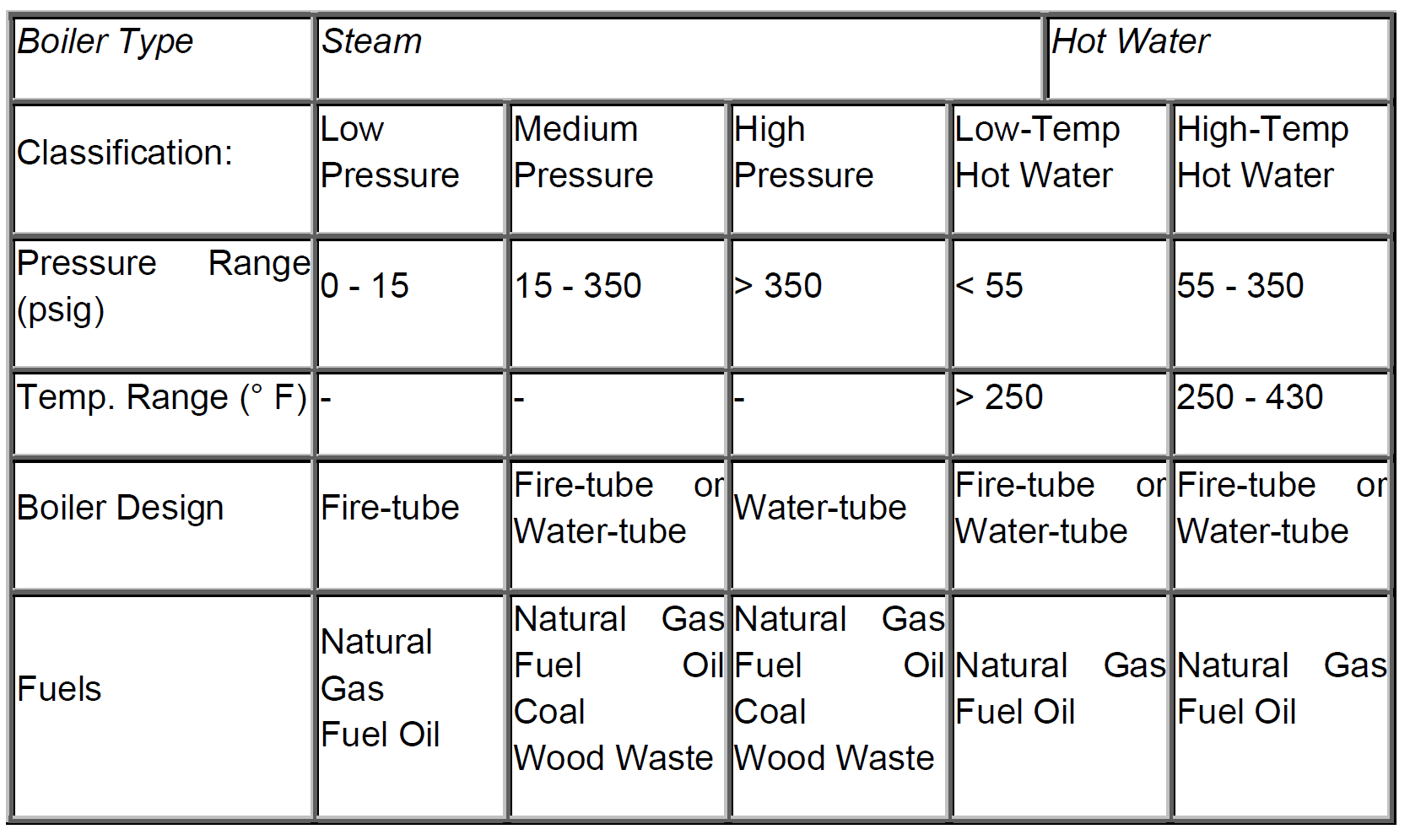

Table 1: Commercial and Industrial Boiler Categories.

2. Typical Applications

Boilers can be used for space heating, water heating, industrial process heating, cogeneration, and more. Most medium-to-large facilities use boilers to generate hot water or steam for space heating, food preparation, and industrial processes. Table 2 provides typical applications of boilers in commercial and industrial facilities.

Table 2: Typical applications of boilers in commercial and industrial facilities

Fuel Types

A boiler can combust natural gas, oil, coal, pulverized coal, wood, or wood waste to heat water. Some boilers can use more than one type of fuel. Burners deliver fuel mixed with air to the combustion chamber in proportions that allow efficient burning. Natural gas or fuel oil generally fuels fire-tube boilers. In addition to burning natural gas and oil, water-tube boilers are more amenable to solid fuels like coal and wood waste than fire-tube boilers.

Steam or Hot Water Distribution Systems

Steam or hot water produced by burning a fuel must be distributed to the point of use (load) by a piping system. At the point of use, the steam or hot water either transfers its heat across a heat exchanger or is injected directly into a process. Heat not consumed or wasted during distribution will be returned to the boiler by a feed water pump in the form of condensed steam or hot water. Re-using condensate or high temperature water allows for more efficient operation than adding colder water from a water main.

CLEANING NOTES

First of you need to get a competent boiler man to assist you. Boilers are very complicated machines and there are many different configurations, an expert with the machine will make navigating the cleaning process simple. With their assistance Alpha Descaler FG can easily be applied to clean your machine.

Water tube boilers are usually harder to clean because scale buildup is harder, usually from the deposits form water treatment. It is mostly rust and scale, which is great and no problem for Alpha Descaler FG to handle! But the only problem since scale can be so hard and often “stuck” in the bent portions of the tubes, they do not discount some manual “rod” cleaning or lancing that may be necessary for the perfect cleaning.

METHOD:

- Shut down boiler (like, if that’s not obvious!)

- Give the boiler a good blow-down with the pressure still on to flush out anything loose.

- Drain and flush

- Add the ALPHA DESCALER or ALPHA DESCALER FG, either by pumping into the mud drum or into the blow down or drain piping.

- Add enough water to fill the steam drum to a point just below the manhole cover.

- Circulate the descaler and water from the mud drum or container used into the open steam drum for at least 8 hours. If it is really dirty, you may need to circulate for up to 24 hours. Watch for foaming activity in the open steam drum. As long as it keeps foaming, keep pumping.

- If some tubes are completely plugged, you may NOT get circulation thru the plugged tubes. It may be a good idea to open the boiler up prior to cleaning if possible to determined badly plugged tubes, otherwise after the cleaning you may have to clean some by using a “lance” where you manually spray the descaler into the tube to push open any blocked holes. If this happens, a second cleaning with less material can be done. When doing such a second cleaning, you simply dilute more but run longer.

- After circulation, flush and refill but you may want to open and inspect first.

Water Tube boilers are difficult to clean so I would consider significant time to make sure it is totally clean. Some tubes that are badly clogged would need to be plugged.

One thing for sure, there is NO WAY normal acid mixed with an inhibitor is going to clean this, especially if it is plugged anywhere. The trick is simple – circulate and vent. If the scale is really bad, it will just need time.

ALL PRODUCTS

-

Alpha Descaler

$175.00 USD – $1,485.00 USD Select options This product has multiple variants. The options may be chosen on the product page -

Alpha Descaler Extra Strength

$250.00 USD – $2,420.00 USD Select options This product has multiple variants. The options may be chosen on the product page -

Alpha Descaler FG

$160.00 USD – $1,210.00 USD Select options This product has multiple variants. The options may be chosen on the product page -

Alpha Descaler FG Extra Strength

$210.00 USD – $1,650.00 USD Select options This product has multiple variants. The options may be chosen on the product page

If you need consulting beyond the scope of a complementary sales inquiry, please contact us by email.